Overview

The rich history of bread making in the fertile and sunny Dobrudja area, known as Bulgaria's Granary, goes back a long time.

The pro-active entrepreneurs in Dobrudja region believed in the words of a wise man who said that no one is larger than bread and handed down to the coming generations his respect to this noble occupation. People have been making bread ever since the world began and our ancestors worshipped it as a relic.

At the beginning of the last century, bread making in Dobrich was thriving. There were between forty and fifty bakeries in the city.

About 90 years ago, in 1934, the Romanian Constantin Dimitrescu decided to expand the capacity of his bakery located at Yordan Yovkov St. This bakery differed from all the others, which is why everyone called it a factory. He established contacts with German companies, signed a contract for the delivery of equipment and dug a well. The water that was essential for kneading the dough gushed from a depth of 2 metres. The dream of the wealthy Romanian came true. Engineers and craftsmen arrived, the equipment was mounted and the furnaces were constructed.

In 1947 the factory was nationalised and became a municipal enterprise. This was the start of the three-shift bread production.

During the 1950s and 1960s the enterprise underwent different structural transformations.

Gradually, bread making gained a new image, research was allowed and attention was paid to training young people. In the 1970s, the construction and equipment of the new bread making plant began.

The new facility was completed in the city of Dobrich in 1975. Until 1979, the bread making plant worked at full capacity, based on a three-shift system. The old Polish equipment was replaced by newer equipment made in the Czech Republic. Special attention was paid to the products sales system.

1997 – The company built its own mill, which was expanded in year 2000 with equipment from the top Swiss manufacturer Bühler AG, with capacity of 150 t per hour. The production was expanded as a result of the new Rommel stone module with capacity of 1 t per hour for production of new high-quality rye, whole grain and Graham flours suitable for diet breads and enriched types of bread.

1998 – A fifth production line was introduced for the production of basic types of bread.

1998 - A new semi-automated production line of the German company MIWE was installed for the production of new innovative white and brown types of bread, sliced and packaged, launched for the first time on the Bulgarian market.

2000 – A new fully automated production line of the company Werner & Pfleiderer was introduced, with capacity of 2400 loaves of bread per hour, for the production of sliced and packaged bread, which was an innovation in the Bulgarian bread making industry and marked the pathway for development of a number of competitors in this field.

2003 – A new production line for basic types of bread was integrated, with capacity of 2400 loaves of bread per hour, with equipment by the German company WINCKLER.

2004 – A new bread making plant was built in Varna.

2005 – The strongest brand of Dobrudjanski Hliab AD was created – "VITA" and the company started producing new diet and healthy breads range under the "VITA" brand.

2006 – Dobrudjanski Hliab introduced a Certified Food Quality and Safety Management System under BSS EN ISO 9001-2008 & HACCP. A certificate was issued by the German certification company TÜV Thüringen e.V.

2009 – The company started producing croutons with bacon, mushrooms and plain croutons in packages of 200 g and 1 kg.

2009 - The company built a new warehouse for finished products and new transport facilities for transportation, cooling and slicing the finished products, which modernised the process and made it fully automated. The modern new warehouse for selling the finished products has five electro-hydraulic levelling loading ramps that can be serviced simultaneously.

2010 – With the assistance of the consulting marketing agencies Partners MMD OOD and NOEMA OOD, the company carried out a marketing audit based on market studies, which was followed by the development of a marketing strategy for the short-term and long-term company development.

2010 – Re-positioning of the diet product range of the Vita breads. Logo and packages re-design. Two healthy sub-series of whole grain breads were introduced – the diet series Vita Silhouette and the healthy series Vita Balance.

2010 – Dobrudjanski Hliab AD and Max Mel EOOD constructed their own automated grain storage facility with a dryer made by the top Italian company MULMIX. The grain storage facility has a capacity of 16 000 t and the production capacity of the equipment is 100 t per hour. An automated flour mixing and conveyor system was also built, as well as additional equipment for improving the mill’s efficiency and, respectively, the flour quality. They were developed with funding from measure 123 of Agriculture State Fund supporting small and medium-sized enterprises.

2011 – Specialised industrial starter culture equipment of the Austrian company HB-Technik was introduced and installed, which brought the production processes to a new and higher level of technology. The starter cultures (starters) input in the production enhanced the products taste and flavour and increased their shelf life.

2011 - New bread cooling conveyor routes (spirals) were built, made by the Italian company ALIT S.r.l.

2011 - A new cutting and packaging machine for basic bread was installed, made by IBONHART, with capacity of 3600 loaves of bread per hour.

2012 – Renovation of the mill laboratory - new laboratory equipment was purchased which brought about a more accurate analysis of flour and flour mixes. The renovation was funded by Operational Programme "Development of the Competitiveness of the Bulgarian Economy", the procedure for certification under internationally recognised standards.

2012 – A new production line was commissioned in the company’s plant in the city of Varna, with fully renovated production capacities. It is designed for the production of specialised and luxury breads, croissants and products made of puff pastry and bunder pastry. The production equipment is made by the German company FRITSCH and the Italian company Mak.Pan.

2012 – The plant in the city of Varna started to produce quick-frozen products under the new brand "TeigMeister".

2012 – The project "Introduction and certification under IFS of Dobrudjanski Hliab AD" under contract ZMS-02-39/01.06.2011 was completed. The existing management system in Dobrudjanski Hliab AD was integrated in line with the requirements of the IFS v.5 for the two company plants.

Today, Dobrudjanski Hliab AD is a modern and dynamic company that respects both tradition and innovation, invests in its human resources, production facilities and capacity in order to offer top quality products to its clients and partners.

The company management believes that their proximity to consumers and their knowledge about the needs of the consumers, the strict production control, the products’ excellent quality and modern image are the key to taking a leading position on the market.

Production

The two company plants in the cities of Dobrich and Varna specialise in the production of bread and bakery products.

The company produces basic (factory-made) types of wheat, rye-wheat and brown breads, toaster breads and diet types of breads, Easter breads, croutons and hardtack, bread crumbs and flours in its production facility in the city of Dobrich.

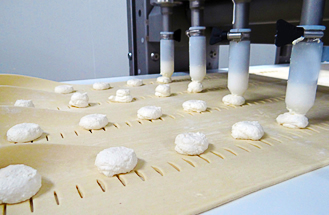

The boutique products are made in the production facility in Varna: HoReCa (resorts, hotels and restaurants) products and bakery products, such as quick-frozen products and fresh products, special and luxury bakery products, snacks from puff pastry and bunder pastry, croissants, Kaiser bread, baguettes and bagels, "rural" and "rustic" type hand-made breads, round loaves, pita breads, etc.

Brands

Dobrudjanski Hliab

We offer a wide variety of freshly baked products under the brand "Dobrudjanski Hliab": Basic and toaster breads, whole grain breads and Easter breads, ritual breads, flour, bread crumbs, croutons, etc. Our registered trademarks are "Dobrudjanski Hliab", "Gergana", "Nashenski vkus", "Dobrotitsa" and other graphic and word marks.

VITA product range

The VITA brand is the leader in the product portfolio of Dobrudjanski Hliab AD with its two series of whole grain products:

Vita Silhouette are 100% whole grain breads without white flour among their ingredients. The diet breads from the Vita Silhouette series are essential for everyone struggling to lose weight. They make following a diet not only effective, but also healthy and tasty.

Vita Balance are whole grain breads boasting a unique balance between good taste and health benefits. They are made of 60% whole grain flour.

TeigMeister

The "TeigMeister" brand includes both freshly baked and frozen products, prepared according to established Austrian, German, Russian and other recipes, which contribute to the variety of the product range and ensure the guaranteed German quality and technology developed by our production lines’ manufacturer.

Baking the products in hearth furnaces gives them a crispy crust and an authentic taste and our own starters used for preparing them not only enhance their taste, but also extend their shelf-life, without adding any preservatives.